|

Pro-Comp™ Computerized Compensation Speeds Operations The OCL400 and OCL430MD utilizes sophisticated electronics and computerized measurements to eliminate the need for manual compensation by the operator. With a touch of a button and a single-point adjustment, any technician can machine a rotor to within OEM specifications in minutes.

Service Each Rotor in Less Than 9 Minutes!

|

|

|

|

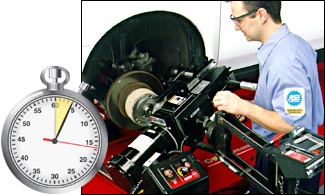

Step 1

Attach adaptor and lathe… |

|

|

|

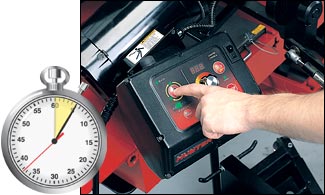

Step 2

Press button for computerized compensation and make a simple single-point adjustment… |

|

|

|

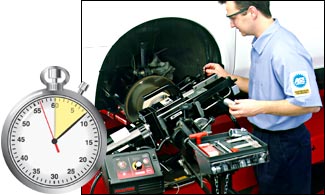

Step 3

Adjust cut depth and machine rotor with “on-the-fly” optimum speed. |

|

Compensation Methods and Models Available |

|

Pro-Comp™ Computerized Runout Compensation

Model OCL400

With a push of a button and a simple single-point adjustment, the OCL400 quickly compensates for lateral runout. Compensation is greatly simplified, no longer requiring time-consuming dial indicators or special tools. Ensures your brake service technician is machining the rotor within OEM specifications. |

|

Rotor is automatically placed at the high point for simple single-point runout elimination. Removes operator guesswork.

|

|

|

Manual Single-Point Compensation

Model OCL360S

Compensation of the hub, adaptor and lathe is achieved with a single-point adjustment. The compensation process is simplified and adjusting time is reduced. |

|

|

|

|

Manual Three-Point Compensation

Model OCL360

Manual three-point runout compensation is accomplished at the adaptor. The lathe is then attached and the rotor machined. |

|

|

|